Bellbrae Fence Overview

AUSTRALIAN MADE

ECO FRIENDLY

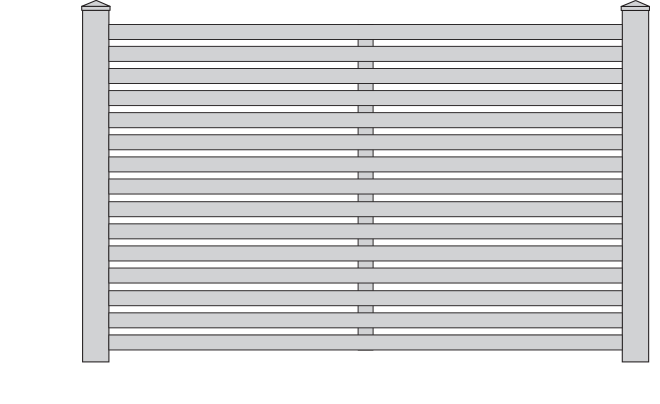

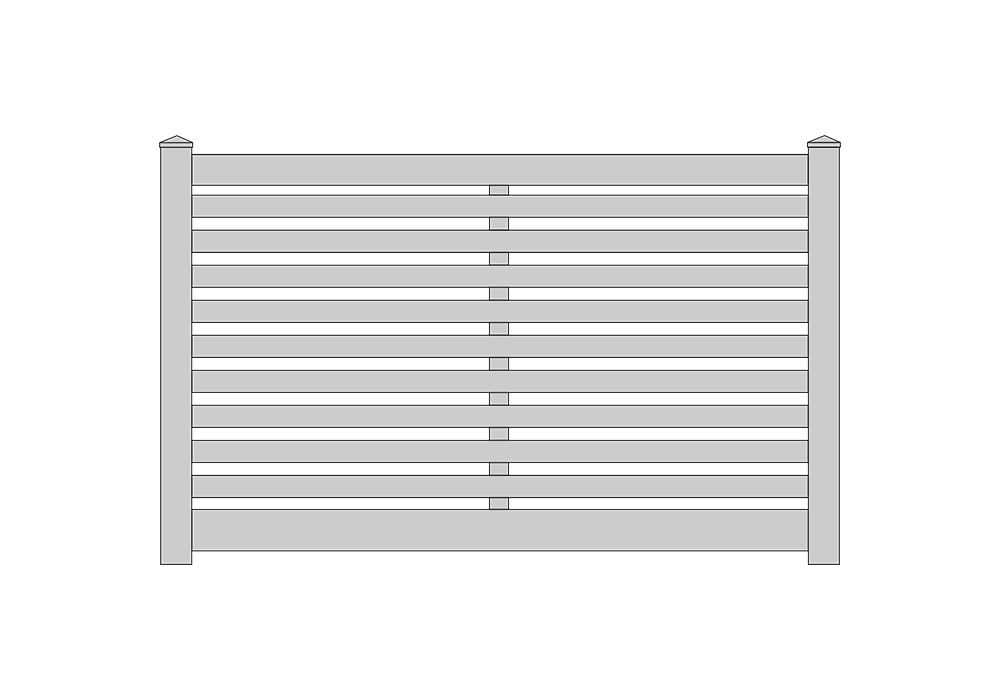

The perfect horizontal slatted semi privacy screening

Bellbrae Fencing gets its name from “Bellbrae” the small coastal town in Southern Victoria, wind swept beaches, rolling sand dunes and idealistic coastal homes.

Modern, clean and open. Bellbrae PVC screening is a horizontal slatted semi privacy screening system that can be configured in a range of heights, colours or styles.

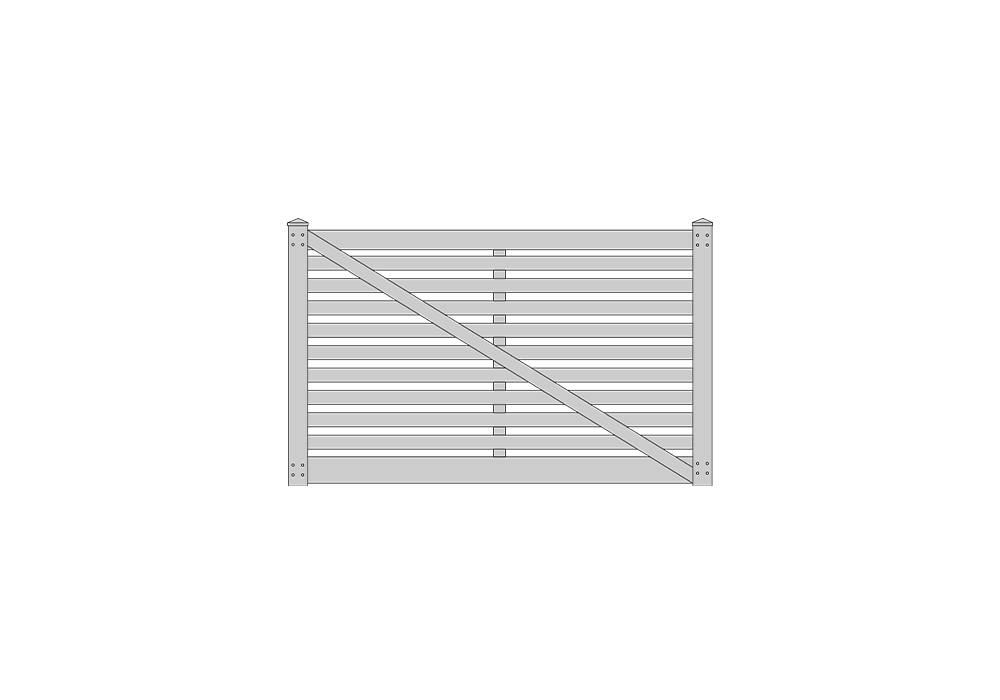

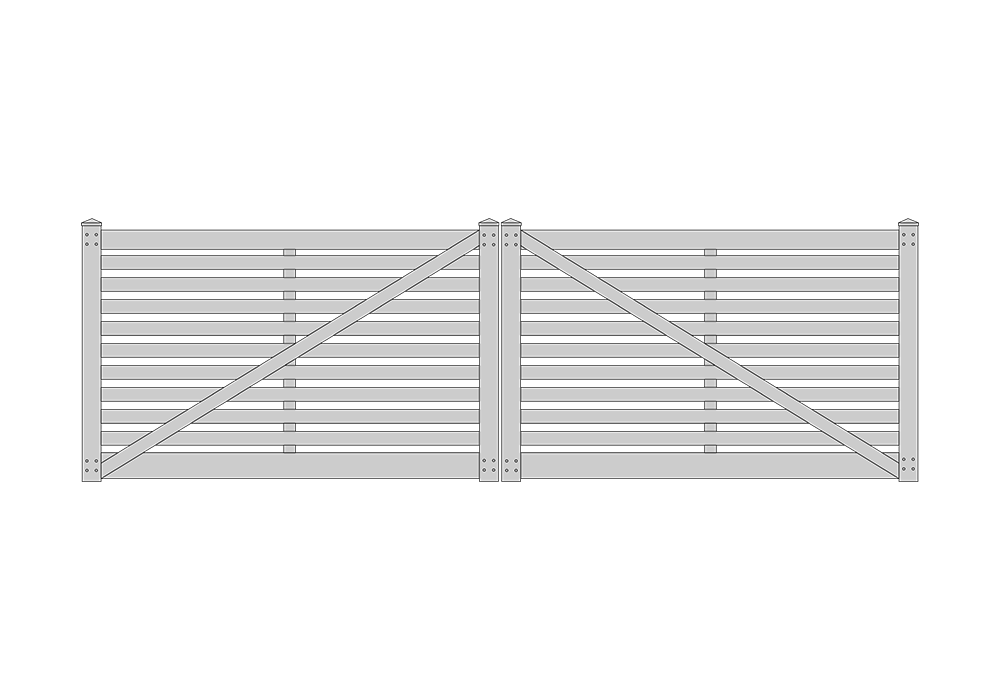

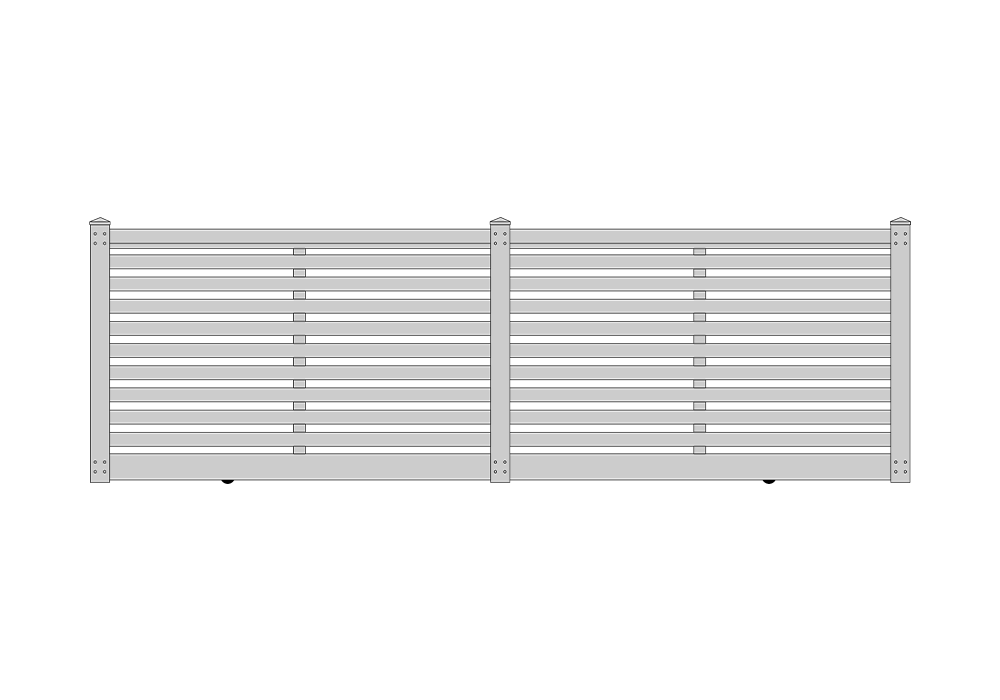

Bellbrae Screen Fence Styles

Quality Slat Fencing

All of our fences are made from durable high tech composites. Consequently our slat fencing retains their good looks year in year out without the need to paint.

Our fence posts have slots cut through both the top rails and plinth boards. For the reason that, it not only enhances the look of your fence but protect its life. Furthermore Think Fencing’s unique slat screen fence designs means our slat fence look just as good from the front or back.

Screen Fencing Redesigned

Bellbrae Screening is perfect for boundary fences, patios, screening, carports or just to hide cluttered corners. The slat style allows breezes and a natural light flow, while increasing your household privacy.

Bellbrae screening can also be attached to brick or concrete piers using our specially designed pollock channel.

It’s available in a range of heights from 0.9m high, up to 1.8m high. The horizontal slats are made using our 76x22mm pickets slotted into the posts. The recommended span post centre to post centre is 2390mm with a support strut mounted in the centre of the panel.

Think Fencing PVC Benefits

We’ve heard all the concerns, perhaps the most popular is; plastic is cheap and won’t last outside in the Australia conditions. If this was true do you think we would offer a 30 year warranty on all our plastic (PVC) fencing.

DIY Installation

So you’re reasonably handy and would like to save some save money, then great news our PVC fencing is easy to install.

ECO Friendly

Despite what you may think about plastics, the PVC used to make out fences are in-fact eco friendly and completely recyclable.

Australian Made

All Think Fencing products are manufactured here in Australia at our Bellarine based manufacturing complex in Victoria.

Lifetime Warranty*

Think Fencing offers a limited *30 year warranty for all PVC Fencing products.

Never Paint Again

Think Fencing doesn’t require painting ever, simple choose from our large colour range and relax knowing it will never require painting.

Graffiti Resistant

We all know fences are easy targets for graffiti artists, rest easy knowing our fences are coated in a graffiti resistant coating.

Simple DIY Installation

No nails or screws required! Think Fencing’s Bellbrae horizontally slatted privacy screen installation is made simple with our special interlocking tabs that join the rail to the posts, so there is no need for specialised tools or fixing parts – consequently maintenance is minimal for the life of your picket fence.

Have a look at our Bellbrae privacy screening fence installation guide to assist you every step of the way.

Bellbrae Flexibility

Bellbrae screening is available in a range of heights from 0.9m high, up to 1.8m high. The horizontal slats are made up by using our 76x22mm pickets slotted into the posts. The recommended span between posts is 2390mm with a support upright mounted in the centre of the panel. The support is then screwed to the back of the pickets at an even spacing.

Belbrae screening can also be attached to brick or concrete piers using our pollock channel.

FACTS BY NUMBERS

Bellbrae Screen Fence Standard Sizing

Custom widths and heights available

WIDTH | HEIGHT |

|---|---|

2390mm | 900mm |

2390mm | 1200mm |

2390mm | 1400mm |

2390mm | 1600mm |

2390mm | 1800mm |